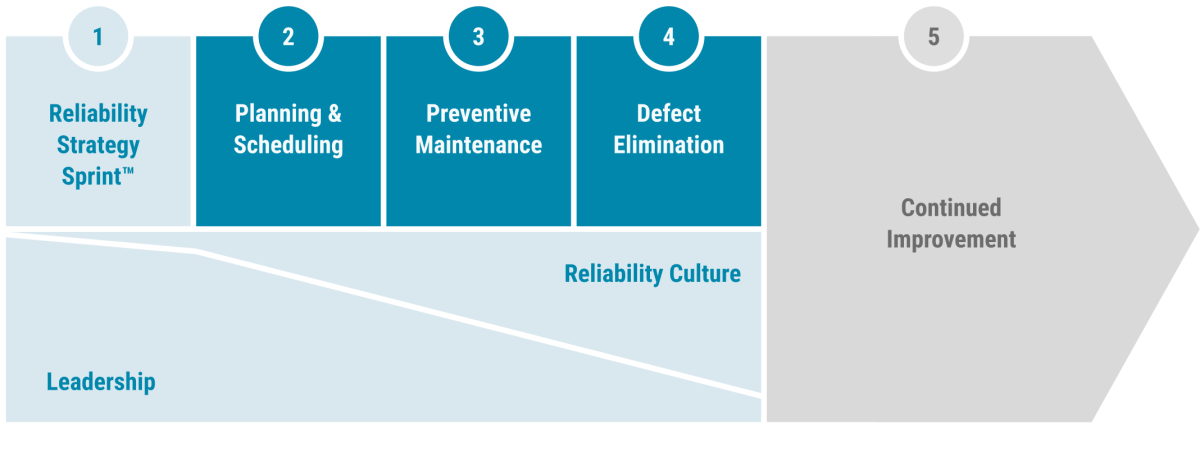

Planning & Scheduling

Increase your maintenance workforce by 35% without hiring anyone. Reduce costs, improve safety and increase morale.

Defect Elimination

80% of failures that occur in a plant have occured before. Fix them forever and stop forever fixing

Preventive Maintenance

40% – 60% of PMs add little value. Learn how to eliminate them to reduce work-load, reduce costs and increase uptime.

Leadership & Culture

70% of change initiatives fail. Without Leadership, you’ll get nowhere. Without Culture, you won’t sustain anything.