Maintenance Planning & Scheduling is one of the 4 Essential Elements on the Road to Reliability™. Planning & scheduling, or work management as it’s often called, ensures the right work gets done, at the right time, with the right tools, materials, and people. Without an effective maintenance planning & scheduling process, you’ll never achieve high reliability. In this article, I’ll explain why that’s the case. I’ll also give an overview of what a planning & scheduling process should look like.

The “best of the best”

But before we do that, let me take you on a short stroll back in time. In the 1980s DuPont commissioned the largest ever benchmarking study of maintenance and reliability practices. It included a study of 3500 sites across North America, Europe, and Japan. It was so extensive that we still refer to it today.

The study concluded that the top 5% of these companies, the so-called “Best of the Best” do the basics very well. And those basics include Planning & Scheduling.

That DuPont study and the many studies since then have repeatedly shown that maintenance productivity is often poor, and typically as low as 20% – 30%. That means that during a typical 10-hour day your average technician only spends 2 to 3 hours doing actual maintenance work. Sometimes even less. So, when you pay your maintenance technicians for a full day’s work you actually only get about 2 to 3 hours of your money’s worth. And no that’s not because your technician isn’t working hard, it’s because you make it too hard for your people to do the right thing. The average day is simply filled with too much inefficiency and waste.

But it doesn’t have to be like that. We know from those same studies that with an effective maintenance planning & scheduling process you can grow your productivity to 45%. And as you continue to improve you can increase your productivity to world-class levels of 55% or 60%.

The benefits of maintenance planning & scheduling

Now, you might not think that moving your productivity from a low 30% to an average of 45% is a major improvement. Not something you should get excited about.

But, you’d be wrong.

Let’s assume for a moment that you work in a typical organisation in an asset-intensive industry. And you have a very typical maintenance productivity, or wrench-time, as many call it, of around 30%.

And let’s assume you put in place a work management process and over time you increase your productivity from 30% to around 45%. In doing so you increase your productive time by 35% without increasing staffing. That means every day, every week, every month you get 35% more work done.

In other words, you have just increased your workforce by 35% without hiring anybody!

In a plant with 50 maintenance workers that could be worth a cool $1,500,000 per year. Maybe that is worth getting excited about?

If you want to get a better understanding of how I put those numbers together, read my article How to Sell Work Management to Your CEO and you’ll see the calculations behind these numbers. And you can download a simple tool to do the same calculations for your own organisation.

Planning & scheduling reduces waste

You achieve these productivity gains because maintenance planning & scheduling tackles inefficiencies and reduces waste. In any organisation, you will find waste, but in a typical maintenance organisation you will find a lot of waste.

Waste in the form of:

- Delays and lost time during the completion of jobs;

- Incorrect identification of materials resulting in false starts, delays or makeshift repairs;

- Poor co-ordination of personnel resulting in excessive waiting and idle time;

- And bad timing of equipment isolation and shutdown resulting in excessive downtime.

The more waste you have the easier it is to drive it out. But apart from driving out waste and making your organisation more efficient, an effective maintenance planning & scheduling process also brings other benefits.

You will find yourself with:

- Improved quality of work, supporting increased reliability;

- Increased uptime and integrity of critical equipment;

- Improved safety by performing work in a prepared way;

- More job satisfaction and a greater sense of ownership among your teams.

And this gain in job satisfaction and ownership is so critical on your Road to Reliability™. It starts to build a reliability culture. A culture that will naturally sustain planning & scheduling and drive continuous improvement.

The improvements in job satisfaction and ownership usually come from:

- Better use of people’s time, with less waste and less frustration. Nobody likes to see their time wasted.

- Making the CMMS work for you and your people, rather than the other way around. Nothing is as frustrating as being a slave to a system.

- Reducing fire-fighting and chasing “someone else’s emergencies”

High reliability? Not without planning & scheduling

As you can see, planning & scheduling drives efficiency in your workforce. You get more work done. Your work environment becomes less reactive. Teams finally find the time to get rid of those recurring problems. Your people are less frustrated and start to see the benefits of a reliability-based culture. And soon enough you will find yourself on the Road to Reliability™.

In the rest of this article, I’ll talk through the main steps of a planning & scheduling process. But before I do that we need to tackle one common misunderstanding.

Planning vs scheduling: they are not the same

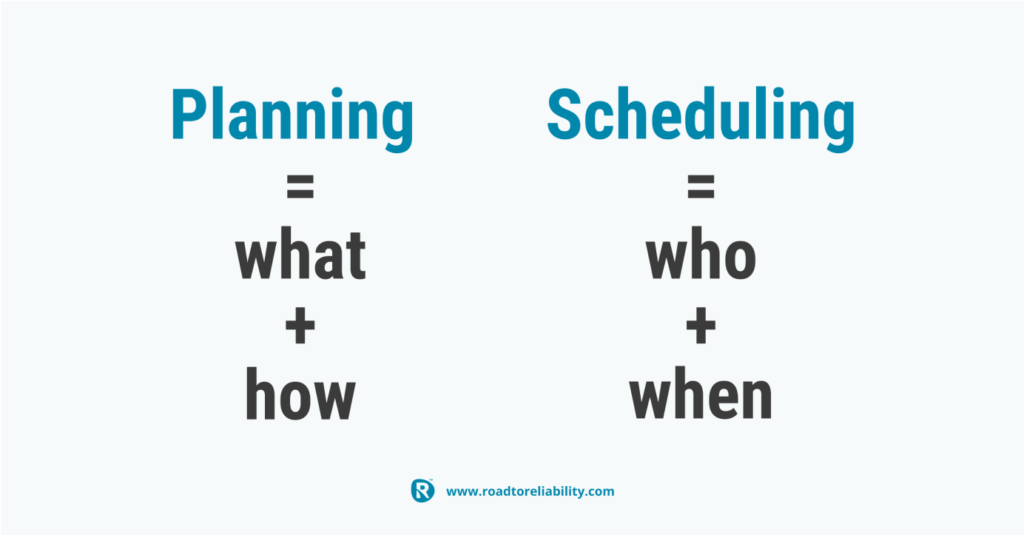

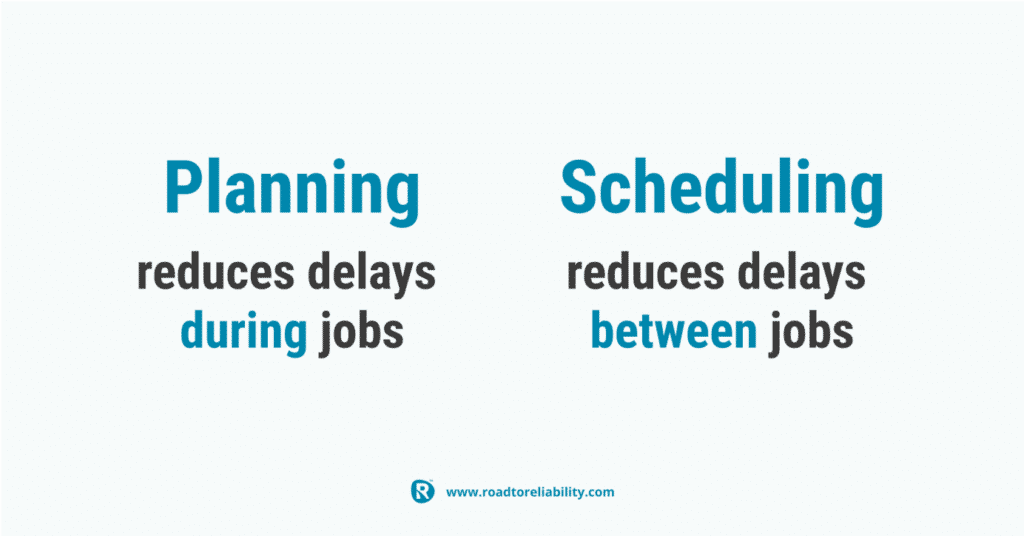

Planning is not the same as Scheduling. This is one of the most misunderstood parts of the work management process.

You see, Planning refers to preparing a job so you can do that job without unnecessary delays. This requires identifying and preparing:

- the scope of work;

- the procedures you’d need to do that work safely and properly;

- the materials you’d need;

- any external (specialist) services;

- any specials tools etc.

Planning maintenance is normally done by a Maintenance Planner. Someone with a trade background, someone with extensive experience and sound technical knowledge.

Scheduling, on the other hand, focuses on what work gets done when and by whom. Scheduling also looks at how you group work to minimise waste. Waste like equipment downtime, travel time etc. Scheduling also balances the workload against available resources.

In simple terms, planning maintenance is about the “WHAT and “HOW” of a maintenance job. And scheduling refers to the “WHO” and “WHEN”.

Another way to look at this is that maintenance planning reduces delays during jobs, whilst scheduling reduces delays between jobs.

To succeed in improving your productivity you need both Planning and Scheduling. Planning alone or scheduling alone just won’t cut it.

The maintenance planning & scheduling process

There are many versions of maintenance planning and scheduling processes floating around. But, in essence, they all come down to the same basic steps outlined in the diagram below:

In the rest of this article, I’ll walk you through the planning & scheduling process in detail.

Note: the process I describe here I will walk you through a corrective maintenance job that starts with someone raising a work request. The process for preventive maintenance is really the same except that the first step of the process is done – or at least should be done – as part of a structured process developing your PM program.

Step 1 – Identify & prioritise

The process starts with creating a quality work request for the new job. An Operator notices a pump has started to leak and raises a work request for maintenance to fix the leak.

Proper identification of the work is essential. That way the Planner gets the right information. And the right amount of information. With this, the planner can prepare the job properly.

To ensure you get high-quality work requests, create a standard for ‘what good’ work looks like. Train your people to that standard and quality check all new work requests.

Review and approve all new work requests on a daily basis. Do this review jointly with your planner, supervisor, and Operations in the room. By doing it as a team effort you get better results that reflect your business priorities. You also start to instill cooperation, understanding, and trust.

As part of the review of the work request – and before approving it – you need to prioritize it. This is one of the most important steps in the process especially for those plants that are still in a reactive environment.

If you fail to prioritise properly you’ll soon find that:

- The frozen weekly schedule is unnecessarily interrupted which increases inefficiency and waste.

- The priorities assigned to work requests in your CMMS become useless. Your planner can no longer rely on the assigned priorities. Your planner will struggle to determine what work to prepare next and become less efficient.

- You become the victim of emotional priorities. People start to inflate the priorities of their work requests to make sure they get done.

For prioritisation, I prefer using a simple 5 x 5 matrix to risk assess new work requests. Something I will discuss in a future post.

So, at the end of this step, you have an approved work request in your CMMS. One that can move to the planning stage when your planner is ready for it.

Step 2 – Plan

Planning maintenance enables accurate scheduling, efficient execution, and quality of work.

As part of the planning step, the Planner identifies all resources, materials, and services required to do a job. And once that’s done your Planner creates a work pack containing all the required information like:

- drawings

- procedures

- OEM documentation

- list of spare parts and consumables

- list of special tools or equipment

- special safety considerations

- shutdown requirements

- access or lifting requirements

Maintenance jobs should not be planned from just behind a desk.

Your maintenance planner should visit the job site to develop the scope of work. Even if the Planner knows the site well, things change. There might be temporary equipment that poses a safety risk. There could be some scaffolding left up that’s blocking access.

Taking pictures of the job site, equipment, and any (access) constraints is helpful. Once back at the desk, the Planner can use these to build the job plan in the CMMS.

Its good practice for the Maintenance Planner to review the scope of work can with a technician or supervisor. Especially if the planner’s primary trade is different than what the job requires.

This builds a sense of ownership for the specific job with the crew who has to execute the work. And over time it will build a better understanding and buy-in for the planning process.

Now, experienced technicians may not like a Maintenance Planner telling them how to do a specific job.

“I have been doing this work for 20 years and I do not need someone to tell me how it’s done!” might ring familiar?

But in reality, if you ask five technicians how to complete a job, you will get five different answers. And variability is the enemy of quality.

It’s the Planner’s duty to prepare the most effective, efficient, and safest way to do a job.

And the Planner has to ensure that all the material and equipment is there to perform it. This means the Planner also places the necessary stock requests or purchase orders.

The planning step ends when a job is fully scoped. Materials are on site, staged, and kitted. And any external services have been (re)confirmed to be on site on the required dates.

At this point, the Maintenance Planner confirms the job as “Ready for Execution”. This flags the handover to the Scheduler and is critical.

Unless all the work that goes into your Weekly Schedule is 100% ready your Weekly Schedule will fail. And the expected productivity improvements won’t materialize.

Once planned a maintenance job should never have to be planned from scratch again.

The Planner should store all information and documentation required to do a job. Next time that job comes up the Planner simply opens the file and re-uses it.

Step 3 – Schedule

It’s the Scheduler’s job to group work in an optimised, coordinated sequence. That it’s performed at the right time by the right people.

To make this happen, the Scheduler prepares a Weekly Schedule which lists all the work due the next week.

The Site Manager owns the Weekly Schedule and reviews and approves the draft Schedule during a Schedule Review Meeting. This meeting is where Operations and Maintenance agree on the work for the next week.

Once approved the Scheduler issues the Frozen Weekly Schedule.

Any work breaking into the Frozen Weekly Schedule has to be approved by the Site Manager. This creates stability and drives efficiency.

To develop a Schedule you need to know the available hours for the following week.

So each week all Supervisors provide the Scheduler with an update of available hours. These updates take into account who is not available for work due to leave, training, etc.

The Scheduler prepares a draft Schedule by matching these hours against a prioritised list of “Ready for Execution” work.

This matching of work against available resources is referred to as Capacity Planning.

You want your Scheduler to assign work for every available work hour. You want to schedule to 100% of your capacity. Don’t allow for emergencies in your Schedule.

As part of his work the Scheduler groups together jobs on the same equipment, system or location. Productivity increases if staff can move from one job to a nearby job. Or do multiple jobs on the same equipment.

Grouping work on the same equipment reduces the number of isolations. It can simplify permitting. It helps to reduce clean-up time, travel time, setup time, etc.

Once issued you want to track compliance against your Frozen Weekly Schedule. Develop a Schedule Compliance KPI and track performance each week

I strongly suggest you also track Emergency Work and Fill-In Work. Emergency work is jobs that are created and executed within the Frozen Week. Fill-In Work is existing work that was not in the Schedule but was still worked on in the Frozen Week.

Tracking these 3 metrics every week will tell you a lot about the health of your work management system.

Step 4 – Execute

The primary aim of execution is to carry out a safe, quality job.

And everything we do in the work management process is to drive efficiency in this step. To maximize the productivity of our maintenance crew.

This step of executing work essentially revolves around a cycle of:

- allocating work

- executing work

- managing emerging work

- reporting daily progress

- and reinstating equipment.

This is the domain of the Maintenance Supervisor.

Your Maintenance Supervisor is responsible for the crew’s safety. And the Maintenance Supervisor is responsible for the quality of the crew’s work. That means your Maintenance Supervisor needs to know his crew well and be fully familiar with their abilities and experience. The allocation of work to crew members is a Supervisor’s responsibility. Not the Schedulers.

The maintenance crew executes the work based on the work packs provided by the Planner. Once the crew starts work they own the work until completion.

If the job requires extra materials or resources the Supervisor must source these. It is not the Planner’s responsibility as the Planner should be planning future work.

Or, if the crew finds they need to complete the work in a different manner than stated in the work pack they manage this. In discussion with the Supervisor.

But, in both cases it’s critical the Planner gets feedback at the end of the job. That way the Planner can improve the job plan and avoid these problems next time.

As the crew progresses a job they might find unexpected work. So-called emergent work. The crew or the Supervisor must determine if they will absorb this extra work. Or if they will execute it as a separate, planned, and scheduled job in the future.

There are no hard and fast rules for this. Experience and common sense should dictate how you manage emergent work.

But remember, the Site Manager must agree to any impact to the Frozen Weekly Schedule.

At the end of each day the crew report progress to the Supervisor for all their jobs in progress. They complete work history and technical history in the CMMS as appropriate.

Step 5 – Close out

The Close Out step covers the reporting of technical history, work history, and areas for improvement.

This is one of the most important steps in the process as without there is no improvement. Unfortunately, it is also one of the steps that many ignore.

As part of this final step the Supervisor:

- Confirms all work is complete and meets the required quality standards;

- Reviews and approves the technical history in the CMMS;

- Makes sure the Planner receives feedback on the quality of the job plan;

- Initiates a Root Cause Analysis if required;

- Ensures unused materials are back in the warehouse;

- And payments are initiated.

Step 6 – Review & improve

Analysing your performance is essential to getting better. You won’t jump from a low 20% or 30% productivity to a world-class performance. That takes time and continuous improvement is the name of the game.

This should take place in various ways.

First of all, continuous improvement should happen within the planning & scheduling process. As part of routine activities and reoccurring meetings. For example, the review of Schedule Compliance during the Weekly Schedule Review Meeting. Or the feedback loop from the execution crew to the Maintenance Planner. With the crew providing feedback on the quality of the job plans.

Second, you should have regular reviews on the planning & scheduling process. Get your Supervisors, Managers and Senior Executives to conduct Planning & Scheduling Gemba Walks.

The aim is for leaders to see the planning & scheduling process in action for themselves. These ‘Go See’ walks are highly effective to:

- find out what works well and why.

- find out what issues frustrate or concern individuals most.

- discover opportunities for improvement and for your Leaders to see how they can help.

And finally, you need to conduct a formal, annual Maintenance Planning & Scheduling Process Audit. A process audit is where you get your process owner to spend a day or two in the field or on the shop floor to assess the health of the process. Spend time with the execution crews. With the Planners, Schedulers, and Supervisors. Agree on what areas for improvement you will focus on. What you need to sustain.

And make it happen.

Key roles

To succeed with work management you need to understand that there are three key roles in the process. These roles are the Planner, Supervisor, and Scheduler. And in principle, they need separate people.

The Maintenance Planner

The Maintenance Planner must prepare the most effective, efficient, and safest way to perform a job. And the Planner has to ensure that all the material and equipment is there to perform it.

The planner role requires detailed technical and equipment knowledge. Your planner is typically someone with a trade background.

The Maintenance Planner focuses on future work. The Planner should not work in the current week or the positive impact on crew productivity is lost.

The Maintenance Scheduler

The Scheduler’s job is to prepare a Frozen Weekly Schedule. The Schedule must balance available hours against agreed work priorities. And the Schedule must drive efficiency.

During the current week, the Scheduler monitors and reports progress. And may help your supervisors manage the impact of break-in work.

The Scheduler coordinates the collation of weekly and monthly performance indicators.

A final task of the Scheduler is to develop a 12-24 months look ahead. This flags major maintenance well in advance, which is critical to managing long-lead items. It also helps to group to maximize efficiency and reduce downtime.

The Maintenance Supervisor

The Supervisor is Mr. Quality and Mr. Safety in one. The Maintenance Supervisor assigns work and ensures it’s executed safely and to the right quality standards.

The Supervisor also plans any emergency work within the current week.

Implementing work management

As you can see, the Maintenance Planning and Scheduling process is in itself easy to understand and not hard to do.

So why is it that so many organisations struggle with? Why do so many organisations have terrible maintenance productivity?

Some of the most common mistakes when it comes to implementing work management are:

- No Change Management

- Picking the wrong person as Planner

- Letting Planners Work in the Current Week

- Not ensuring execution readiness before scheduling work incl. kitting and staging

- Not providing or acting on feedback

- Poor backlog management

- Incorrect set of metrics to measure performance or driving the wrong behaviour

We address these mistakes and much more aspects of implementing planning & scheduling in our article: How to Implement Maintenance Planning & Scheduling.