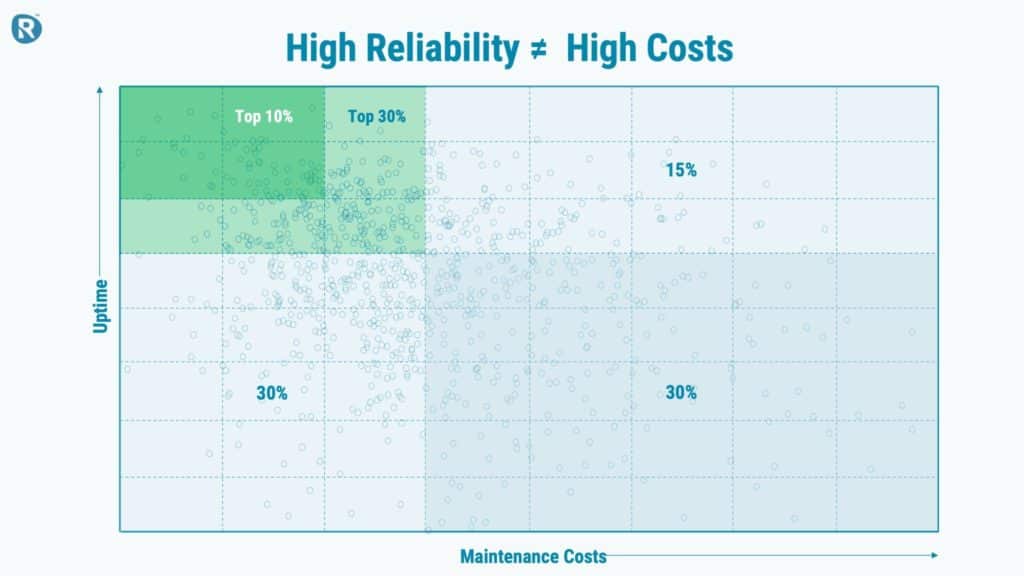

Many organisations believe that achieving high reliability is expensive.

But it doesn’t have to be. The inconvenient truth is—

A vast majority of plants around the world still experience low reliability despite the high costs of their maintenance.

These plants invest in…

… shiny new software

… complicated frameworks

… expensive contractors

But don’t see significant returns on their investments.

They are still stuck in the firefighting.

Still running around chasing parts.

Still overwhelmed with a big backlog.

When the expensive and complicated solutions don’t work, they feel that high reliability is just too difficult, too expensive to attain.

Their mindset blinds them from the real issue—

It is ‘the basics’ that actually bring results. They rely too much on advanced “solutions” without having a solid foundation of the ‘basics’ in place. That’s why their improvement initiatives don’t work, no matter how expensive they are.

You have to understand that you can improve your reliability WITHOUT spending too much money by focusing on building a solid foundation.

In fact…

There’s a small group of companies out there that have already achieved high reliability with little cost.

If you look at what they do, you’ll notice that they simply do ‘the basics’ really well.

Reliability isn’t about whether or not you’re a big or small company that has fancy tools.

It’s about implementing the essentials properly.

(which any plant can implement)

That’s why before you start investing in complicated frameworks or software, you have to go back and master ‘the basics’.

Your organisation must learn how to…

Properly implement Maintenance Planning & Scheduling.

Eliminate recurring defects and fix them forever instead of forever fixing.

Remove maintenance tasks that aren’t really adding any value so you can focus your scarce resources on tasks that do matter.

By having an effective process for these three, you will start seeing amazing results in your plant reliability.

If you want to start improving your reliability WITHOUT spending thousands of dollars on tools, software, and complicated frameworks…

Then start by learning how to implement the first element of the Road to Reliability: Planning & Scheduling