Research and experience show that up to 60% of Preventive Maintenance (PM) tasks aren’t really adding value — all they do is just take time and money away from your already very limited resource pool.

Some of the most common reasons for this are:

- Tasks are duplicated.

- Tasks are done too frequently or not frequent enough

- Tasks are not effective at addressing the failure mode

- Too many fixed-time, intrusive overhaul tasks that would be more effective, less costly, and less disruptive to production if they were condition-based.

- Lack of using existing failure data and experience to set good task frequencies.

Yet far worse is that not only do these tasks add no value, they blind us to critical and high-risk problems that actually need our attention.

The companies that know this have already undergone programs to improve and optimise their PM programs. But those results are often not in the public domain.

Luckily, there’s a published case study that is arguably one of the most striking examples showing how there’s so much waste in our PM. It’s the comparison of two airplanes: The DC-8 and the DC-10.

The comparison goes like this:

The DC-8’s maintenance schedule was developed using traditional, time-based concepts — you replace components before they reach a certain “age”, in hopes to prevent failure.

Using this maintenance schedule, the DC-8 crew overhauled 339 components and called for more than 4,000,000 labour hours before reaching 20,000 operating hours (and no, that is not a typo!).

On the other hand…

The DC-10’s maintenance schedule was derived by applying Reliability Centered Maintenance.

This required only 7 component overhauls and 66,000 labour hours to reach the same 20,000 operating hours!

You can see the extraordinary amount of resources that were saved, despite the DC-10 actually being the bigger, more complex plane.

The benefits of RCM are significant and have been demonstrated many times over. Yet in industry, RCM is notorious for being resource-intensive and hard to get results from.

That’s why you don’t need to apply RCM to everything. You can simply apply the foundational principles of RCM in your PM program with a lot less effort by applying the following 9 principles of modern preventive maintenance:

Principle #1: Accept failures

Not all failures can be prevented by maintenance. In some cases, the impact of the failure is so low that we simply accept it. Good maintenance programs don’t try to prevent every failure.

Principle #2: Most failures are not age-related

Over 70% of failure modes are not age-related. In these cases, there is no point in doing time-based life-renewal tasks like servicing or replacement. Condition monitoring would be more effective.

Principle #3: Some failures matter more than others

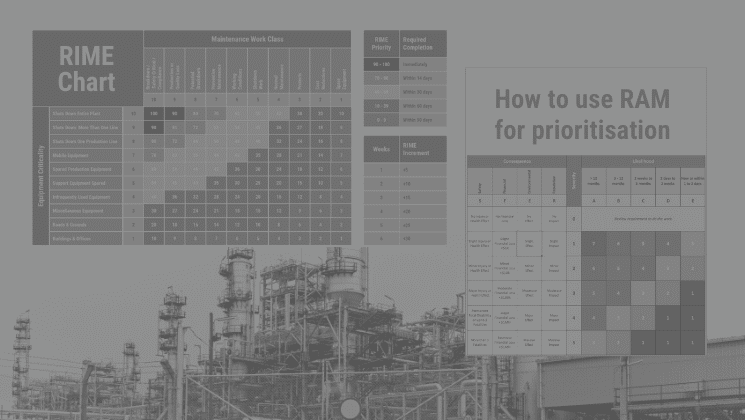

Good maintenance programs are risk-based. They consider both the consequence and the likelihood of failure. They use this information to assess where to use our scarce resources to get the greatest benefit.

Principle #4: Parts might wear out, but your equipment breaks down

Parts are simple components that have their own failure modes and failure patterns. Most modern machinery consists of many parts and should be treated as complex items.

Because complex items have so many different failure modes, they don’t typically exhibit wear out, which makes time-based overhauls ineffective and wasteful.

Principle #5: Hidden failures must be found

Hidden failures are failures that remain undetected during normal operation. They’re often associated with equipment with protective functions. These failures only become evident when you need an item to work and it doesn’t (failure on demand), or when you conduct a failure-finding task.

Principle #6: Identical equipment does not mean identical maintenance

It’s possible to have two identical pieces of equipment operating in very different contexts (e.g., the classic duty-versus-standby case). A difference in criticality can also lead to different maintenance needs.

Principle #7: “You can’t maintain your way to reliability”

No amount of maintenance can raise the inherent reliability of a design. When a poor design is the cause of poor reliability or performance, the only solution is to change the design.

Principle #8: Good maintenance programs don’t waste your resources

Completing tasks that don’t add value, maintaining an unnecessary level of performance, and assigning multiple tasks to a single failure mode are all examples of wasteful practices that should be avoided.

Principle #9: Good maintenance programs become better maintenance programs

The most effective maintenance programs are dynamic and continuously improving. These programs look for ways to eliminate unnecessary tasks, convert time-based tasks into condition-based tasks, and extend task intervals.

Now that you’ve come to realize the 9 principles of modern preventive maintenance, the question now is this: How do you use these principles to improve your preventive maintenance program?

If you’re interested, then you can answer that question by reading about it here: How to improve your preventive maintenance program.