Maintenance Planning and Scheduling Training Course in Dubai

Learn what maintenance planning & scheduling is, how it creates value, and how to successfully implement it in your organisation.

Then create and pitch your business case and improvement plan in our face-to-face workshop in Dubai before presenting it to your own management.

Unique 'Flipped Classroom' Learning Experience

We have been running our hugely successful online training in Maintenance Planning & Scheduling for multiple years and have trained over 1000 professionals, across 100 companies and 50+ different countries.

Now we are offering a unique ‘Flipped Classroom’ experience which combines a 10-week online learning experience with a 4-day workshop in Dubai.

In the first 10 weeks of online learning you will go through our self-paced PS100 training course, but in a cohort of 12 to 16 students. Every week you will meet virtually with your Course Director (Erik Hupje) to discuss content and to answer questions.

After the 10 weeks of online learning we will meet for a 4-day face-to-face workshop held in Dubai. During the workshop you will work on, and present parts of, your self-assessment, your improvement plan and business case. At the end of the workshop you will be ready to present to your own management.

Course Objectives

This flipped classroom learning event builds on our very successful PS100 Implementing Maintenance Planning & Scheduling training course to provide you not only with the knowledge and understanding of how planning & scheduling should work in an industrial environment, but also how to implement it.

Throughout this fully online course, we help you to understand how planning & scheduling will add value to your business. And we teach you how to implement planning & scheduling using a proven framework that combines both project management and change management principles.

You will conduct a detailed assessment of your current planning & scheduling practices, using what you learn in the course you will develop an improvement plan based on your findings and then create a compelling business case that you can present to your management.

This is a hands-on course, so you will not only learn the theory of planning & scheduling, you will also create a complete and comprehensive plan to improve your company’s performance and then pitch that to your management. Do it well and you will kick off a major improvement program and really add value to your business and enhance your own career.

Here’s what you will learn:

You will learn how to build a business case for implementing or improving planning & scheduling in your business and how to sell this to your leadership. This includes how to estimate the value planning & scheduling can bring to your organisation, which we’ll do using the Wrench Time Calculator.

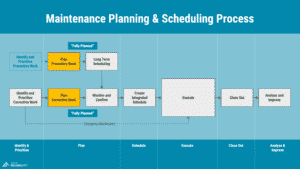

You will learn the key elements in the maintenance planning & scheduling business process and how they interact with each other. This includes developing a planning & scheduling business process flow specific for your organization.

You will learn the key elements in the maintenance planning & scheduling business process and how they interact with each other. This includes developing a planning & scheduling business process flow specific for your organization.

And much more… from setting quality standards for new work request, to the most important planning & scheduling KPIs and how to calculate them, to how to deal with emergent work during the execution phase and how to get on top of the large amount of emergency work that most reactive maintenance organisation struggle with.

Course Structure - Online Phase

The first 10 weeks of this course you will complete our PS100 Implementing Maintenance Planning & Scheduling course but in a private cohort with live sessions each week, in addition to the pre-recorded course videos.

The PS100 course is broken down into 10 modules, each module consisting of individual lessons. In total there are 48 lessons and approximately 15 hours of pre-recorded videos.

In this module, we start the real work. After a brief exploration of the role of maintenance in asset-intensive industries, we’ll explore why we need planning & scheduling.

We’ll cover the increase in productivity and what that means for the bottom line of the business you work for. But we’ll also explore other key benefits of planning & scheduling that are maybe less tangible like workforce motivation and safety.

In the final lesson of the module we touch on some critical characteristics of maintenance work that influence how we set up a successful maintenance planning & scheduling process.

Module 3 is all about work is initiated and prioritised. Fail to get this right and you’ll continue to chase your tail and will not get out of the reactive maintenance model.

Most organisations don’t realise how critical this step is. Most managers and supervisors don’t want to spend the time getting this right.

In this module I will explain why you don’t want to be making that mistake and why putting a lot of effort into creating quality work requests and prioritising them properly is so critical to your success.

And in the last lesson, we’ll touch on some KPIs that you can use to measure your success.

Module 4 is all about maintenance planning, why it is important and the 6 Maintenance Planning Principles that underpin a sound maintenance planning process.

We’ll talk quite a lot about roles & responsibilities because this is where many organisations go wrong. They burden their maintenance planners with work that should be done by others and in doing so they never reach the productivity improvement they were aiming for.

We’ll also discuss the level of detail that is required in a maintenance work order, what makes a good ‘work pack’ and we’ll touch on common mistakes and some useful KPIs.

This is a step in the planning & scheduling process that is not often talked about, but it’s key to your success.

Once the work is planned, all materials are ordered, and purchase orders have gone out for external services you need to keep an eye out on when vendors are available, when materials will arrive at site etc.

And when that’s all in place, you need to flag the planned work in your CMMS as ‘Ready for Execution’ as a handover point to the Scheduler.

Module 6 is all about scheduling. We’ll talk about how scheduling is different from planning and why you need both.

We’ll discuss 5 basic scheduling principles including why you need to schedule for a Frozen Week. how to build up your Weekly Schedule. And we’ll delve into capacity planning plus we’ll talk about some basic scheduling techniques and concepts.

As usual, our last lesson in this module will cover KPIs in this case those KPIs that you can use to drive your scheduling process, for example, Weekly Schedule Compliance.

Module 7 is all about executing the maintenance work that has been planned and scheduled. This is the core of the process and a lot of what we do in planning & scheduling is to drive efficiency in this part of the process.

We’ll focus extensively on the role of the maintenance supervisor. We’ll discuss in detail how you need to manage Emergency Work. And we’ll touch on how you should be dealing with Emergent Work, the work you discover whilst doing a job.

Module 8 covers the close out of work. This is where we capture everything that went well and the things that didn’t go too well.

We provide feedback to the planner in terms of planning quality, materials etc. and we capture technical history in the CMMS so the reliability engineers can use that information in their continuous improvement programs. We’ll also discuss how this links into your Defect Elimination and Root Cause Analysis processes.

The secret to successful planning & scheduling is a continuous improvement loop and that relies on the proper close-out of work and high-quality feedback.

Module 9 is all about making things better and better or in other words: Continuous improvement and how to build that into your business and your work processes.

We’ll delve into using KPIs to drive performance and the limits to what KPIs can do for you. We’ll talk about the need to have a ‘process owner’ who conducts annual process ‘audits’ and the value of GEMBA walks.

In Lesson 4 of this module, we’ll touch on a contentious subject – measuring wrench time. How to do it, when to do it and when not.

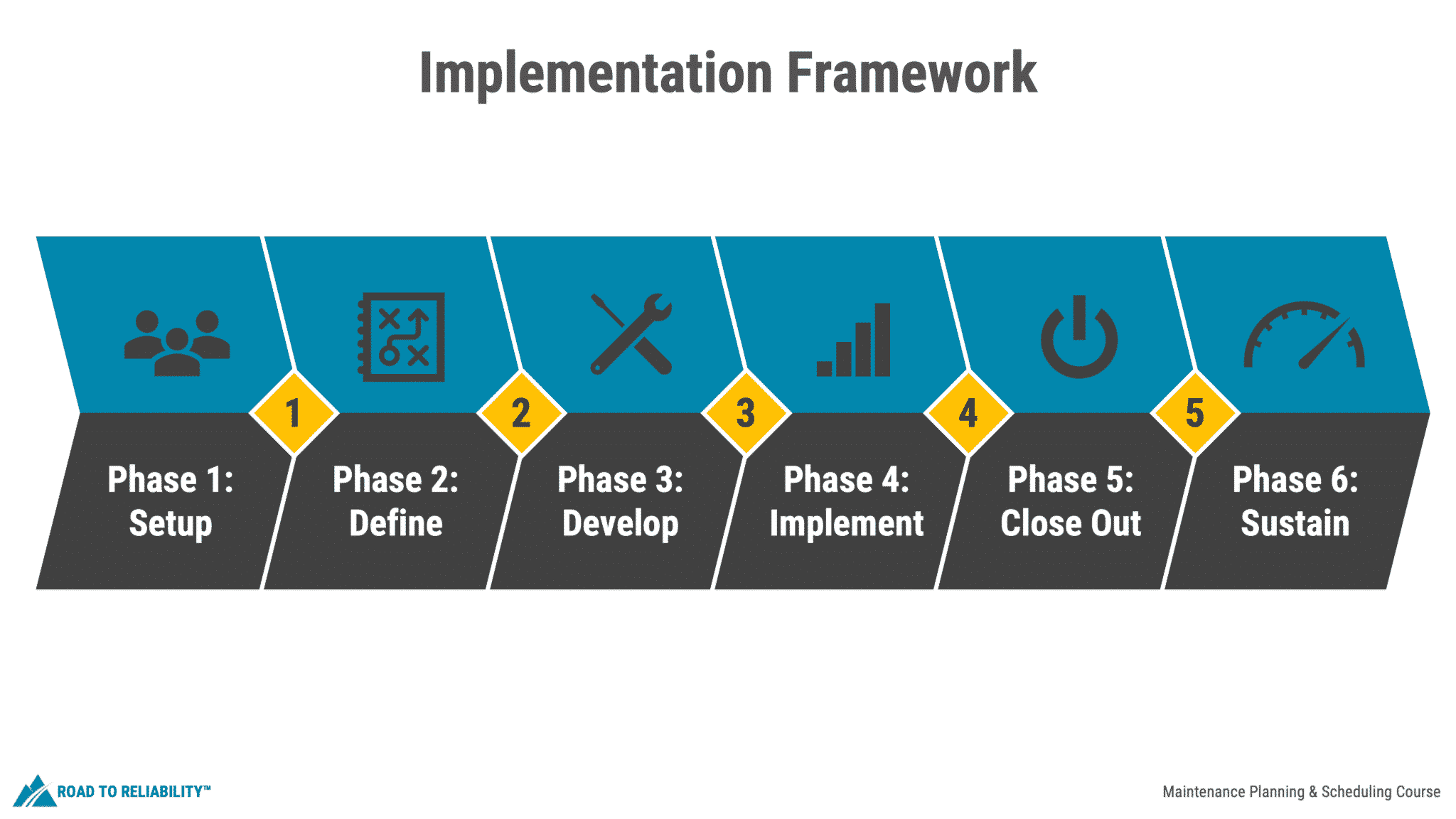

Module 10 is where this course is completely different from all the other planning & scheduling courses out there. In this module, we will give you a tried and tested process to implement planning & scheduling in your organisation.

We’ll cover the business case, change management basics, setting up your project team for success, the need for coaching and each lesson comes complete with practical tools and techniques that are proven to work when it comes to implementing planning & scheduling in a real business environment.

Meet your teacher

My passion is for continues improvement and keeping things simple. Through the Road to Reliability I help Maintenance & Reliability professionals around the globe – people like yourself – improve their plant’s reliability and their organisation’s bottom line.

I am a Certified Maintenance & Reliability Practitioner (CMRP), Certified Reliability Leader (CRL), Certified Asset Management Assessor (CAMA) and a Chartered Professional Engineer (CPEng).

– Erik Hupjé

Course Structure - Dubai Workshop

After the 10 weeks of online learning we meet for a 4-day face-to-face workshop in Dubai. The workshop in Dubai will be focussed on getting you to complete the key deliverables you started during the online phase and then present parts of these during the workshop for feedback:

Using our Planning & Scheduling Audit Tool you will conduct an in-depth review of your current planning & scheduling process and practices.

You will start this assessment in Week 5 of the course so that you are ready to present your findings during the face-to-face Workshop.

Using your detail Planing & Scheduling Audit you will develop a list of recommended improvements which you will prioritize and assess in terms of impact as well as effort to implement

Based on the identified improvements, your stakeholder analysis, and other pre-work you will create a clear, concise, and practical Project Charter supported by a resourced implementation plan.

Approximately 30, 60, and 90 days after the Dubai workshop we will follow up with you to ensure you have indeed pitched the improvement proposal to your management and obtained the go-ahead!

What's included

Lifetime access to the PS100 online course:

- 48 Lessons totaling 14 hours of videos

- Course slides (PDF), Transcript (PDF) and Audio of all lessons (MP3)

- Certificate of completion (PDF)

- Life Q&A sessions

4-day workshop in Dubai:

- Personal feedback on your improvement plan, business case, and presentation

- Learn and network with a small group of highly motivated professionals

- The opportunity to really create an ORI for your organisation and boost your own career

All the resourced you need to succeed:

- All templates required to document the Planning & Scheduling process

- Complete set of change management & implementation tools

- Cohort of motivated professionals

- Personal review and feedback of your Key Deliverables

Cost & Schedule

Key Dates:

- 5th July 2023: we will kick off the course with a live online meeting on Wednesyda 5th July 2023 which starts the 10-week online learning phase. Each Wednesday we will meet live for Q&A.

- 11th to 14th September 2023: Face-to-Face workshop in Dubai (venue to be confirmed). The exact workshop schedule will be provided at a later stage but these will be full days from approximately 8am to 5pm.

Cost:

- The course fee will be USD 3,950.

- Course fees include lifetime access to our PS100 online course and attendance to the 4-day Dubai Workshop. Accommodation, flights, and other travel expenses are at the participant’s own cost.

- Course fees will need to be paid in advance and spots are limited to 16.

Course Schedule:

This will be an intense course, and to get the value out of it you will need to do a lot of work. Here is what the week-to-week schedule will look like:

| Week | Dates | Focus | WK 1 | 5 July 2023 | Kick Off Session (incl. PS100 Module 1) |

|---|---|---|

| WK 2 | 12 July 2023 | Recap of PS100 Modules 2 & 3 |

| WK 3 | 19 July 2023 | Recap of PS100 Modules 4 & 5 |

| WK 4 | 26 July 2023 | Recap of PS100 Modules 6 & 7 |

| WK 5 | 2 August 2023 | Recap of PS100 Modules 8 & 9 |

| WK 6 | 9 August 2023 | Recap of PS100 Module 10 |

| WK 7 | 16 August 2023 | Complete P&S Audit |

| WK 8 | 23 August 2023 | Build Your Business Case |

| WK 9 | 30 August 2023 | Create Your Implementation Plan |

| WK 10 | 6 September 2023 | Catch-up Week |

| WK 11 | 11 - 14 September 2023 | Face-to-Face Workshop! |

Pre-Register Today

There will be a limited number of seats (16) so we are asking everyone who is interested to pre-register using the form below

Dubai Planning & Scheduling Course FAQs

The course is provided by R2 Reliability Pty Ltd which was an Approved Education Provider accredited by the Society for Maintenance & Reliability Professionals. Unfortunately, the SMRP discontinued their Approved Education provider program in 2020. The course continues to offer the same high-quality content when it was accredited by the SMRP, however, we can no longer promote the course as such. We are looking for other international accreditation options. The course can still be used for credit hours towards ongoing professional development and maintaining your CMRP status.

Yes, you will have homework to do. This is an intensive course with assignments that you need to complete in your workplace and submit online. Your assignments will be reviewed and you will receive personal feedback either from myself and/or by a specialised maintenance planning & scheduling coach.

Yes, in addition to the assignments and quizzes that are included in the various modules there is a final, online multiple–choice exam that you need to complete and pass to receive your Certificate of Completion.

Immediately if you want, as soon as you purchase the course you will have access to the course content and will be able to start learning everythgin you need to know about Maintenance Planning & Scheduling

You certainly do. When you have successfully completed all Course Modules, all homework assignments, all quizzes and you have passed the final (online) exam you will automatically receive a Certificate of Completion.

Absolutely, not a problem. Simply drop me an email at [email protected] with your full details and the number of people you want to enrol and I can get a quotation off to you.

I offer a 30-day no questions asked, full refund policy, on the condition that you have not completed the course. However, once the 30 days have passed no refunds will be given.

No! Not at all, the course will be delivered through a web-based Learning Management System, but all you need is a modern web browser like Chrome, Internet Explorer or Safari.

You do need a reasonably reliable internet connection, but as the course material is all pre-recorded you can choose when and where you view or listen to the course content. And on what device as you can access the course on a desktop, tablet or smartphone.

Not yet, at the moment the course is only available in English.

However, there have requests for other language versions like French, Spanish, Arabic and Italian so other language versions are planned for late 2020.

If you sign-up for the English language version and get the Professional or Corporate Edition you will have lifetime access to the course, and that will include other language versions when they become available.

Yes, we have a standard table for volume discounts which are applied when companies purchase the course for multiple students.

The best option is to review the Corporate offer and that will give you the opportunity to schedule a call with me and we can talk through all the options.

P.S. Getting your Planning & Scheduling in order is really one of the most important steps you can make on the Road to Reliability™. With planning & scheduling you create more stability in your work, increase efficiency and finally make some time for proactive maintenance activities.