Why risk-based criticality assessment is a waste of time

Introduction Some people might hate me for saying this, but I need to put this out there: Risk-based criticality assessment is a waste of time. It’s more of an academic exercise rather than a practical one. Many people advocate for criticality assessment because you “need to know your critical assets“. When you read articles, books, […]

My Personal Journey to Escaping the Vicious Cycle of Reactive Maintenance

Working in a highly reactive maintenance environment is extremely stressful. Imagine being trapped in a never-ending cycle of chaos, where every day brings a new crisis to manage, and you’re constantly trying to figure how to put out fires. This is the reality for many professionals working in a highly reactive maintenance environment. The relentless […]

Maintenance Planners deserve BETTER.

Maintenance Planners are the unsung heroes responsible for increasing your team’s productivity by at least 30%, translating to hundreds of thousands, if not millions, of dollars saved each and every year. Yet, despite the immense value they create, planners are often undervalued, and their role is misunderstood in many organizations. In this article, we’ll dive […]

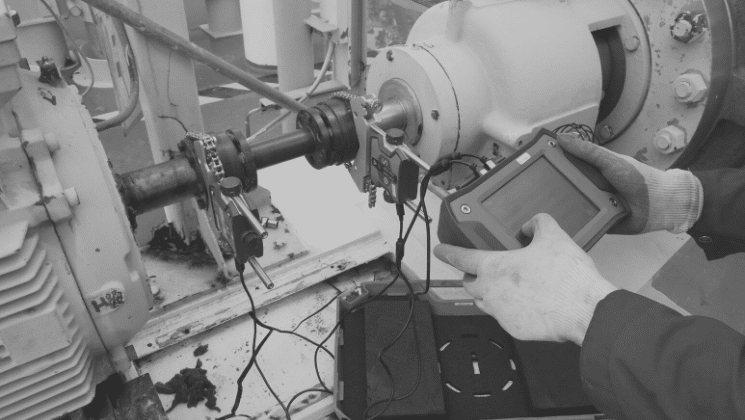

Technology is great, but the basics will make or break you

Diving headfirst into new technology might seem like a good idea at first. Especially when it comes to improving your plant’s reliability. In fact, when I ask my students and clients what their strategy is for improving their plant’s reliability, two common strategies that often come up are investing in a new CMMS…. or better […]

You can’t maintain your way to reliability

We often hear the phrase “maintenance is key to reliability”. And while it’s true that proper maintenance is important, it’s not the only factor that determines your plant’s reliability. In fact, relying solely on maintenance to ensure reliability can be dangerous to your organisation. In this short article, I’ll explain why that’s the case. Maintenance […]

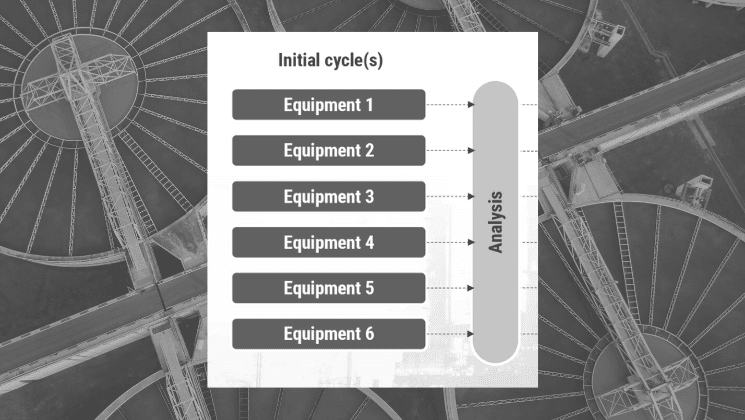

5 Common Mistakes in Reliability Centered Maintenance (RCM)

Reliability Centered Maintenance (RCM) is not an easy process to complete. Along the way, you will likely make mistakes, or identify things you could do better next time round. That’s fine. That’s continuous improvement. But what you don’t want to do, is to start up an RCM study making some of the fundamental mistakes that […]

What is Reliability Centered Maintenance?

Have you ever wondered how efficient we can get with our preventive maintenance tasks? Is there some sort of maximum efficiency that only the Gods of maintenance know of? Maybe. But for mortals like us, there is what I call a gold standard that we can strive for. It’s called Reliability Centered Maintenance (RCM). To […]

What is Risk-based Maintenance (RbM)?

As maintenance practitioners, we have a responsibility to maximise our scarce maintenance resources. Especially since maintenance is often subject to tough budget cuts. We need to be as efficient as we can when it comes to our preventive maintenance. That’s why good preventive maintenance programs and maintenance strategies don’t try to fix everything. They are […]

How to Close Out Maintenance Work Orders

In the Maintenance Planning & Scheduling process, close out work is the phase where we capture the information needed for continuous improvement. We collect data on: What went well?What can be improved?What didn’t produce good results? Sadly, close out is often seen as an admin burden.A waste of precious time.Something you don’t want to hassle […]

3 Major Sources of Waste in Maintenance

The concept of Lean has been around for a long time, but the concept of lean maintenance is not talked about that much. There are a few books written on the topic, but if I’m honest not enough is written about lean maintenance considering how important it actually is in our journey towards higher reliability. […]