3 Simple Steps to Escaping the Vicious Cycle of Reactive Maintenance

Many organisations are stuck in a ‘vicious cycle of reactive maintenance’. It’s an all-too-common situation. Once you finally get that emergency fixed and resolved… you

Many organisations are stuck in a ‘vicious cycle of reactive maintenance’. It’s an all-too-common situation. Once you finally get that emergency fixed and resolved… you

Many of our tasks are automated. But just imagine that you need to manually do some of those. For example, collect and process data from

Is doing more maintenance ‘good’? It’s common to think so. I mean, it makes sense that the more maintenance you do… the less likely your

Delve deeper into a topic with our In-Depth Articles that provide action knowledge:

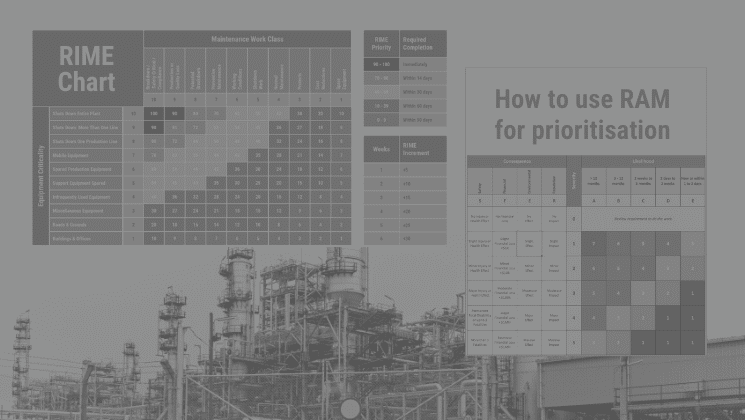

Maintenance Planning & Scheduling is one of the 4 Essential Elements on the Road to Reliability™. Planning & scheduling, or work management as it’s often called, ensures the right work gets done, at the right time, with the right tools, materials, and people. Without an effective maintenance planning & scheduling process, you’ll never achieve high reliability. In this article, I’ll explain why that’s the case. I’ll also give an overview of what a planning & scheduling process should look like. The "best of the best" But before we do that, let me take you on a short stroll back in

Most industrial plants around the world are trapped in the vicious cycle of reactive maintenance. These plants and their teams silently suffer from low reliability, high maintenance costs, low morale, and too much stress. Unfortunately, the journey to create a Reliable Plant has been made unnecessarily complex. In this article, I will show you how to escape the reactive maintenance environment in 4 simple steps. The Reactive Maintenance Trap But first, let’s set the scene. Imagine it's a typical Tuesday afternoon when suddenly, a critical piece of equipment fails. Production grinds to a halt, stress levels soar, and you're at

This article first appeared in reliable plant. You can read the first version of this article here. Many maintenance organisations around the world are reactive. They experience excessive breakdowns, low productivity, and high maintenance costs. To break this reactive cycle, a common solution organisations implement is Condition-Based Maintenance. The problem is this strategy rarely works. They pay for CBM solutions but get the results of a run-to-failure strategy. Here’s how to avoid that. Condition Based Maintenance (CBM) technologies are some of the most sold solutions in the field of maintenance. And with the recent interest in AI and the Industrial

When it comes to improving reliability in your plant, culture is key to your long term success. Without establishing the right culture your hard-won improvements will simply erode over time. And before you know it, you’ll be back in that vicious cycle of reactive maintenance. But what is reliability culture? And how do you measure it? Can you even measure it? In this article, I will introduce the “Reliability Culture Ladder". It is a simple concept to help you assess your reliability culture. A Word of Warning: This is a long, in-depth article. I share in detail how I explored

This section contains the articles that are the most read by our viewers:

Maintenance Planning & Scheduling is one of the 4 Essential Elements on the Road to Reliability™. Planning & scheduling, or work management as it’s often

Most industrial plants around the world are trapped in the vicious cycle of reactive maintenance. These plants and their teams silently suffer from low reliability,

This article first appeared in reliable plant. You can read the first version of this article here. Many maintenance organisations around the world are reactive.

Address:

Level 54/111 Eagle Street

Brisbane City, QLD 4000

Australia

Phone: +61 (0)7 3040 7525

Email: [email protected]

© 2017-2023 R2 Reliability Pty Ltd. All Rights Reserved. | Privacy Policy | Terms of Use | Cookie Settings

© 2017-2023 R2 Reliability Pty Ltd.

All Rights Reserved. | Privacy Policy | Terms of Use | Cookie Settings

© 2017-2023 R2 Reliability Pty Ltd.

All Rights Reserved. | Privacy Policy | Terms of Use | Cookie Settings