Many implementations of Maintenance Planning and Scheduling fail. Often because senior management was never on board to begin with. In this article, I’ll show you how to fix that. I’ll show you how to sell Planning & Scheduling to your CEO. And in such a way that he actually wants you to implement it successfully. I’ll talk about your ‘CEO’, but it could also be your Plant Manager that you need to convince.

Maintenance planning and scheduling is often your first step

Implementing Planning & Scheduling is a critical step in fighting your reactive work environment. And often it’s the first step in your journey to World Class Maintenance. You must get that first step right.

Planning and Scheduling is one of the biggest improvements you can make in your journey to reliability. But it doesn’t come easy.

And like most things in life it doesn’t come free either.

It will cost you time and money to implement a robust work and productivity management system. And for most organisations that will mean getting approvals from senior management.

So the question is: how are you going to sell the benefits of maintenance planning & scheduling to your management, to your CEO?

When it comes to selling something you have put yourself in your customer’s shoes. What’s in it for them?

Before you try to pitch work management to your CEO because “it’s what we need…”

Or because “that’s what everybody else does…”

Think about it from your CEO’s position.

What’s in it for him?

Maintenance planning and scheduling has a great Return On Investment (ROI)

Any CEO worth his salt should be interested in the benefits maintenance planning & scheduling will bring to his operations:

- Work management will result in productivity improvement, which reduces costs.

- Effective maintenance planning and scheduling reduces emergency work. And Emergency work has been shown to cost 3-4 times that of well-planned and scheduled work. So more cost savings.

- Good work and productivity management will reduce equipment downtime so it increases production. More production means more profit.

- And the stable working environment that comes with planning & scheduling is better for safety.

In short, there is a massive return on investment for implementing maintenance planning and scheduling.

Your CEO should like it. In fact, he should love it.

But it gets better. Few maintenance improvements drive so much benefit for so little upfront investment.

And it is relatively easy to demonstrate the benefits up front. There are plenty of case studies, benchmarks and literature sources available to back up your claims.

It should be an easy pitch really.

But somehow it seldom is.

And frequently the message is lost in translation. That is a loss for you and a loss for your CEO – even if he doesn’t know it.

So here‘s a step-by-step framework to help you sell maintenance planning and scheduling to your CEO.

Step 1 – Highlight the problem: low productivity

If your organisation is like any typical organisation, chances are it’s been a while since the CEO has been out on the shop floor. It will have been a while since he talked to the maintenance crew to see how things are going.

Most likely your CEO doesn’t know he has a problem in this space.

So why would he want to spend time and resources on a solution for a problem he doesn’t know he has?

Make it simple for him to see the waste, to see the problem, to see the lost value.

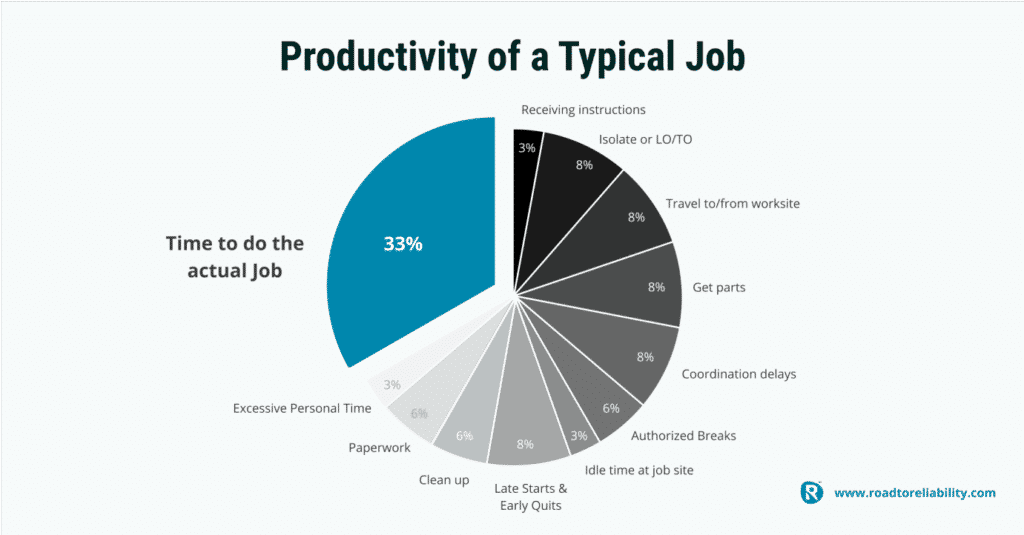

You see the real hands-on productive time of a typical maintenance worker is somewhere around 20% to 30% if you take into account all forms of waste.

And this is not something I’ve made up. Those numbers are well established in benchmarking case studies and industry literature. You can read more about it here.

Below is just one example of how that time ‘waste’ often occurs:

The first thing you need to do is to assess the size of your maintenance productivity problem. That means you identify all the various forms of waste and calculate your wrench time.

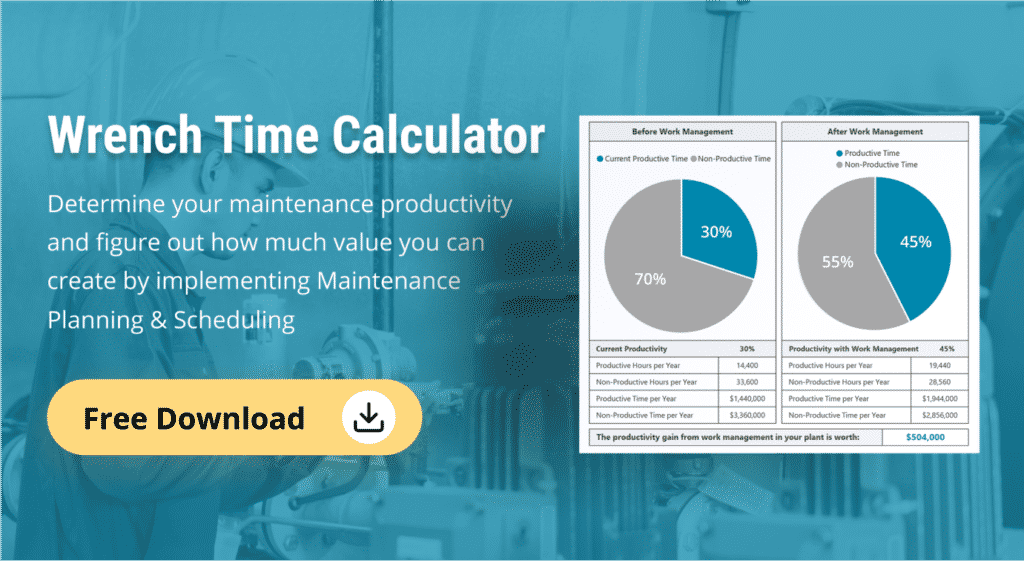

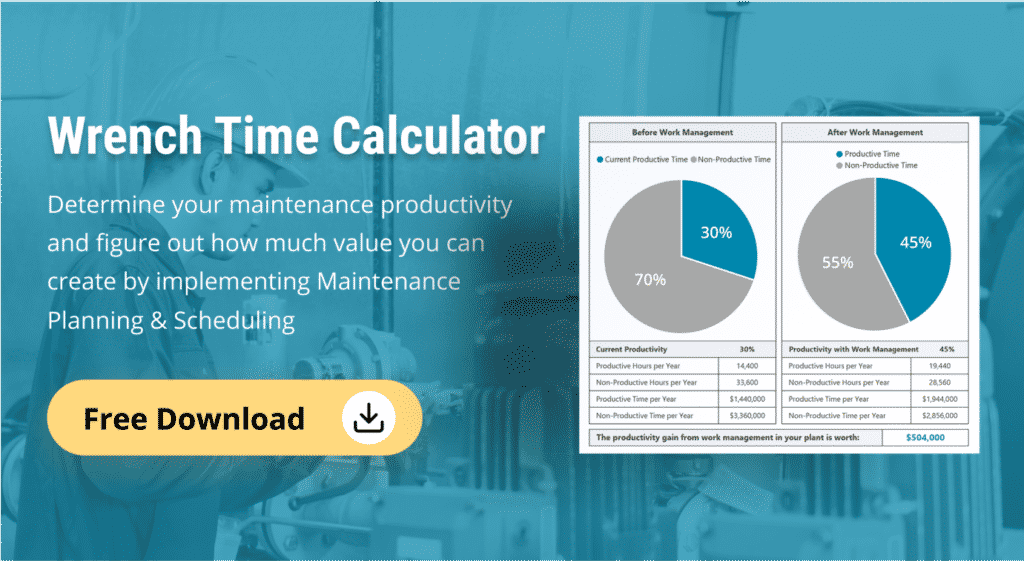

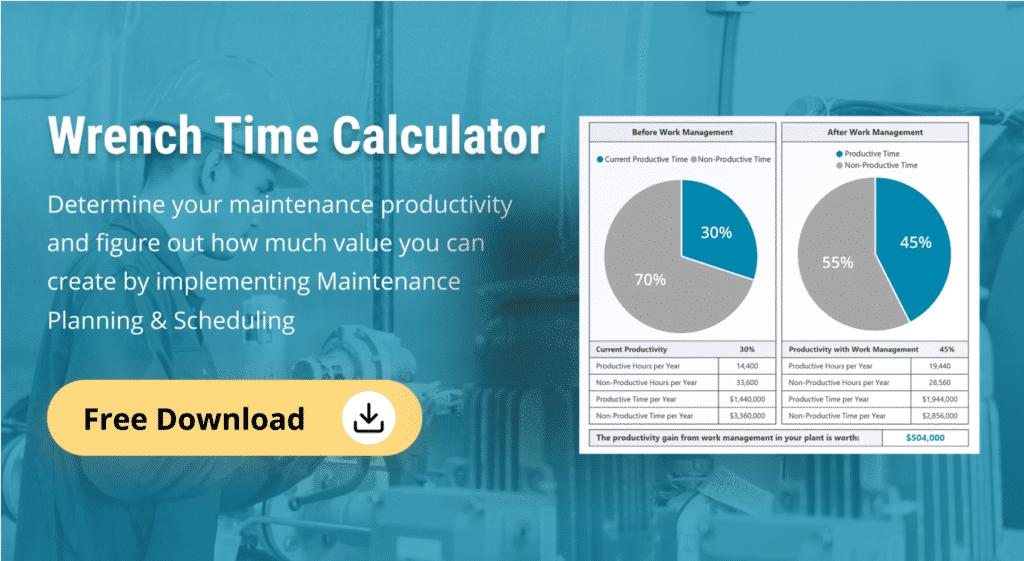

To help you here I created a simple Wrench Time Calculator (MS Excel) that helps you calculate your productivity. The graph you see above was created using this free tool. And you can easily create one specific to your organisation. Simply download it by clicking the banner below:

When you start this productivity assessment I strongly recommend keeping it simple.

Credible, but simple.

To ensure credibility you need talk to supervisors and other stakeholders to get an idea of how much time is lost on typical activities like finding parts, getting tools or waiting on permits.

But keep it simple and don’t go overboard. Don’t kick off an exhaustive time and motion study or statistical analysis of hands on tool time. That can come much later.

If you don’t have a sound work and productivity management system in place your maintenance productivity is likely to be between 20% and 30%.

Spending a massive amount of time and energy to determine whether your wrench time is 27.6% or 31.4% is just a waste.

Instead, use that energy on understanding the essentials of work management. How to successfully implement it. And equally important, how to sell work management to your CEO and the wider organisation.

Step 2 – Explain the solution: Maintenance Planning & Scheduling

Once you have completed Step 1 you’ll know your typical wrench time. And you’ll have an idea of how big your productivity problem is.

Let’s assume your wrench time is 30% and that you aim to get this to a very realistic 45%. That’s pretty typical for a well-functioning work management system. But certainly not world-class. Learn more about wrench time optimization here, in our sample course material available for free.

When you show your CEO that your current wrench time is 30% and explain your aim to bring it to 45% you’ll need to talk him through the basics of effective planning and scheduling.

You need to explain in simple terms how you’re going to fix this productivity problem. At this point, it is still very much your problem – not his.

This shouldn’t be too hard to do.

The purpose of maintenance planning and scheduling is to ensure the right work gets done, at the right place and time, with the right tools, materials and people. All with minimal waste.

And I won’t go into the details of maintenance planning and scheduling in this article. You can read a detailed overview of maintenance planning and scheduling here.

For the purposes of this article, just remember that you need to talk your CEO through the basic steps of work and productivity management. And show him how they solve your productivity problems.

You’ll need to highlight that maintenance planning and scheduling is a process. A business process that will require people to work in specific roles like that of a planner or a scheduler.

Roles you may not yet have in your organisation.

So at this point, it is crucial to reinforce to your CEO that you do not necessarily need more people.

By changing the way you work you will get more out of your existing staff.

Chances are your CEO will ask why the heck you aren’t already doing this. Once someone understands work management it is hard to see why you wouldn’t work like this.

It might lead to some uncomfortable moments, but this is exactly what you want.

It means your CEO gets it and that’s an important first step.

Step 3 – Demonstrate the value of Maintenance Planning & Scheduling

At this point, you have clearly demonstrated that you have a productivity problem. And you’ll have explained that there is a well-established, robust process to help you improve your wrench time.

But that won’t be enough for your CEO.

You need to show him the money.

Don’t stick to generic benchmarks. Instead, calculate the value work management will bring to your organisation. Show him how you will improve his bottom line.

So how do you do that?

Well if you haven’t already downloaded our Wrench Time Calculator go ahead and do that right now. The tool not only helps you to calculate your wrench time as required in Step 1. It also calculates the value of implementing work management in your organisation.

When you open the Wrench Time Calculator and go to the tab for Step 3 you will be asked to enter your current wrench time. Let’s assume that’s 30%. And you need to enter a target wrench time. Let’s set that at 45%.

That’s not an arbitrary number.

Benchmarking and industry experience show that effective maintenance planning and scheduling can increase your wrench time to 45%.

World-Class organizations achieve around 55% wrench time. But that’s not what we’re after here, at least not in the first instance.

You need to calculate your current productive hours without work management based on your existing crew size. Then calculate your productivity once you put in place work management and have a dedicated planner(s) and scheduler(s) in your team.

The difference is your productivity improvement or productivity gain.

I’ll walk you through the example that is in the wrench time calculator.

Assume we have a small organisation with 20 technicians who work five 10-hour shifts per week for 48 weeks per year.

A typical industry ratio of planner-to-technicians is 1:20 to 1:30.

In other words, an experienced planner in a stable, non-reactive maintenance environment should be able to plan work for 20 to 30 technicians.

Let’s assume the bottom end of that ratio and we have twenty technicians without planning & scheduling.

These 20 technicians work at a typical industry average wrench time of 30% for a 10-hour day.

That means over the course of a week they can liquidate 20 x 10 x 5 x 30% = 300 productive hours of maintenance work.

We now introduce planning & scheduling. But we promised the CEO that we would not need more people, so we take 2 technicians and make one a planner and one a scheduler. That leaves us with 18 technicians, but after a transition period, we will achieve the typical 45% wrench time across their 10-hour days. That means that we now liquidate 18 x 10 x 5 x 45% = 405 productive maintenance hours per week.

Even though we reduced our number of technicians we have gained 105 productive hours in a single week. That’s is a 35% productivity gain!

The conventional way to increase your manhours by 35% from a 20-man crew would be to hire another 7 technicians.

And that is the beauty of maintenance planning and scheduling. You achieve that same 35% increase in productivity without recruiting any additional staff.

That 35% productivity improvement equates to 5040 hours of extra work done per year. Assuming a nice round value of $100 per hour the monetary value of that productivity gain is worth over $500,000 per year.

$500,000 this year, $500,000 next year, $500,000 the year after and value will keep on rolling in.

When you implement maintenance planning and scheduling across large sites or large organisations with potentially hundreds of technicians the value work management delivers is simply massive.

Run this calculation for a larger sized organisation with 200 technicians, putting in place 8 planners and 2 schedulers and you will create over $6 million worth of value each and every year.

And that is exactly the way to sell work management to your CEO – by showing him the money.

Step 4 – Summarize the costs and benefits

You now have clearly demonstrated the value planning and scheduling will bring to your organisation. But as I said in the introduction: planning & scheduling doesn’t come for free.

It will take time and money to implement, something we’ll talk about in detail in another article.

When pulling the estimate together to implement planning and scheduling think about:

- The time and resources you need to define and document the new process

- The effort involved in cleaning up your CMMS. And possibly implementing some modifications to your CMMS to enable the new workflow (e.g. work order statuses, reports)

- The time and resources you need to train all the staff in the new processes

- What it will take to coach your teams and ensure the ways of working are sustained and become the normal way of doing things

- And finally, you need to allow time for the overall project management to implement these changes. Change management efforts should be a big part of this.

Once you have the total picture of the costs, time and resources involved summarize it and compare it to the value planning & scheduling will bring.

You should see a payback within 12 months.

Step 5 – Close the sale

With all the groundwork done you now need to create the opportunity to sell this to your CEO and other stakeholders.

Prepare a simple presentation using the graphs and data you generated using the wrench time calculator.

Don’t kid yourself.

You only have a few minutes to pitch this and only one chance, so you need to get it right.

Keep the message simple, effective, and short.

Focus on the bottom line benefits, avoid jargon and enjoy the opportunity.

Sow the seed with your CEO and other stakeholders that this is a change forever – not just a once-off program.

That planning and scheduling is an Essential Step on The Road to Reliability™.

Good luck and let us know how it goes!