Diving headfirst into new technology might seem like a good idea at first. Especially when it comes to improving your plant’s reliability. In fact, when I ask my students and clients what their strategy is for improving their plant’s reliability, two common strategies that often come up are investing in a new CMMS…. or better Condition Based Maintenance (CBM) software or hardware designed to identify the early signs of failure.

But without mastering the basics—without having the foundations in place—you might just be setting yourself up for disappointment with these technologies. You could be spending hundreds of thousands of dollars on promises made by contractors and software providers but get no real return on your investment. Because the truth is, rarely do these efforts move the needle when it comes to long-term plant reliability – unless you have the basics in place.

I know because I went this route several times when I was still working as a Maintenance & Reliability Manager. I realised then that no amount of software or technology will save the day if you are still stuck in a reactive maintenance environment.

And this is one of the reasons many leaders are reluctant to invest in maintenance or reliability improvement… they’ve been stung too many times by improvement projects that promoted software and technology to save the day, but simply failed to deliver in the end.

It is important to remember that the basics of maintenance are still essential, even in the 21st century, maybe even more so. Technology is great, but the basics will make or break you. That means you need to have the following foundations in place:

Implementing an effective Maintenance Planning & Scheduling Process

Before anything else, you need to have an effective maintenance planning & scheduling process in place. Without it, you will continuously suffer from emergencies, firefighting, and an overload of backlog.

You need to create a stable working environment, with a Frozen Weekly Schedule that balances the workload with available capacity and is actively protected from break-ins.

You need to focus on all the things that create waste in your day-to-day maintenance work and tackling them to steadily improve productivity and eliminate your team’s frustrations.

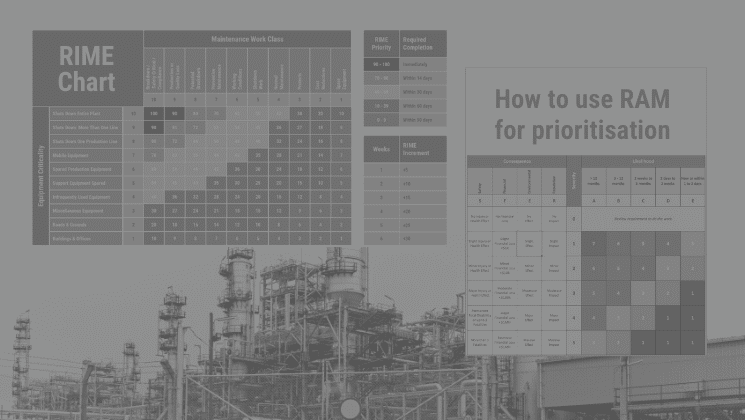

Improving your Preventive Maintenance Program

Many organisations suffer from poor preventive maintenance programs where almost half of the tasks are not really adding value.

You need to have an effective and efficient preventive maintenance program that is based on credible failure modes. Understand the consequences of those failure modes and accept that failure is sometimes the best option.

Make sure that your PM program follows the 9 principles of an effective PM program so that you don’t waste your already very limited resources.

Having a Defect Elimination process in place

Even when you set out to improve the reliability of your plant, you’ll continue to experience failures. Chances are, many of those failures have already happened before.

By applying Root Cause Analysis and establishing a Defect Elimination culture, you can make big strides in improving your reliability by making sure those failures never happen again.

Identify your defects and repeat failures and eliminate them once and for all. Don’t get good at fixing the same failures over and over. Get good at fixing things forever.

Good leadership and a culture of reliability

Without leadership you’ll get nowhere, without culture you won’t sustain anything. Leadership is required to embed all the changes along the way to make sure it all sticks and doesn’t become the flavour of last month.

Leadership is required to build the right culture – a reliability culture, because without the right culture all that change that you implement won’t be sustained. And this starts by ensuring that your maintenance personnel are well trained and equipped to perform their tasks.

By focusing on these relatively simple practices, you can ensure that your maintenance is effective and that over time your plant reliability will improve… EVEN IF you don’t have access to the latest technology.

You need to take a step back and focus on these fundamentals – planning and scheduling, optimizing your PM programs, and defect elimination. By doing so, you’ll be laying the groundwork for success.

Trust me, it’ll be worth it in the long run.

Not only will you save yourself from the headaches that come with poorly implemented technology, but you’ll also set your business up for long-term success.