Complicated solutions aren’t always the right choice.

They may look colorful and flashy—but they’re not always effective. Sometimes, the best solutions are the simplest. They cost less money, take less time to do, and they’re easier to understand.

But the thing is… humans like complex solutions.

And here’s why:

I read a study saying—

“If we have two solutions to a difficult problem, it’s our natural tendency to pick the fancier solution over the simpler one.”

Not because it’s more effective… But because we believe the simpler solution “won’t work”. This behaviour is called complexity bias.

Just as buyers intuitively think a more expensive product is better than a cheap product, people think a more complex solution is better than a simple solution.

The reason for this is that our brains tend to use the path of least resistance. The easiest way out. And by picking the complicated solution, we have a reason NOT to understand how it works.

We simply believe that it WILL work because we correlate complexity with effectivity.

That’s one reason why we engineers love complicated solutions.

Since we constantly face many difficult challenges everyday — some we don’t fully understand—we err on the side of safety, on the side of complexity.

As a result… when we optimize our work processes — we routinely make things unnecessarily complicated.

This is very apparent when it comes to reliability.

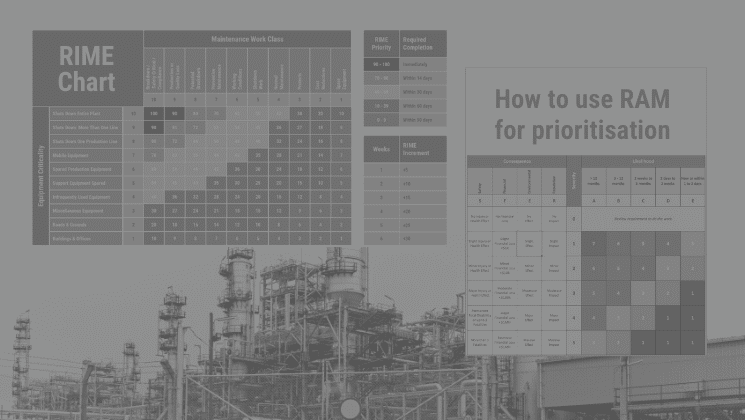

Low reliability is a problem that has a simple and effective solution. Yet too many organizations choose the complex path. That’s why you’ll see models and frameworks asking you to implement 10 to 20 elements to master reliability.

But the problem is that most companies are not ready for world-class reliability. Most companies still struggle with—

… low productivity

… too many repeat failures

… fire fighting culture

And when you struggle with the basics, trying to implement a complex framework with 10 or 20 new practices just won’t work.

If you think about it, Pareto’s principle can be applied here: 80% of the results (improving reliability) comes from only 20% of the elements you see on those complicated frameworks.

That’s why I always emphasize the effectiveness of simple yet proven frameworks like the Road to Reliability.

In fact, in my 20+ years of experience in the industry, I’ve seen plants improve their reliability greatly by simply doing the basics extremely well.

By focusing on the foundational elements, you can get the most results from only implementing four elements—

Planning & Scheduling

Preventive Maintenance

Defect Elimination

Leadership & Culture

If you want to start mastering reliability, then you first have to master these four elements. If you’d like to start, you can check out the first course in your Road to Reliability.