“Why should we bother with scheduling?”

“Is planning the job not enough?”

“How is scheduling going to increase our productivity?”

Plenty of my clients and students have asked me these questions.

So, here’s the bitter truth:

Even if you had world-class planning…

It won’t be enough to achieve high productivity.

Because planning alone will only help you do individual jobs better.

While Planning aims to reduce delays DURING jobs… Scheduling aims to reduce delays BETWEEN jobs.

And scheduling does so in several ways:

- Through goal setting

- Driving discipline

- The grouping of work

- Enabling staging,

- And coordination.

If you want to get a LOT more work done, you will need to implement BOTH planning & scheduling.

In fact…

Experience and various benchmarking studies have shown that planning without scheduling has almost no sustained impact on overall productivity.

One way to explain this is by using 2 very familiar laws: Murphy’s Law and Parkinson’s Law.

Murphy’s Laws states that, “Whatever can go wrong, will go wrong.” And planning is about anticipating problems that might occur during a job and making sure that we’re ready for those. This becomes especially important in big jobs like major overhauls or shutdowns.

On the other hand…

Parkinson’s Law states that, “The amount of work assigned will expand to the time available.” This means if you need to complete two tasks today, you will get those done within the day.

And often what happens, you end up using all the available time to complete those 2 tasks, even if they can be finished in half a day.

It’s just human nature. And it’s highly inefficient.

But if you’re well prepared and have scheduled six things to do for the day, the pressure is on and most likely you’ll get those six things done. And that is what scheduling is all about.

Scheduling is essentially goal-setting for your maintenance crew.

It’s about giving your maintenance crew a clear list of things to do that week and making sure that they have the resources to complete that list of work. You don’t want your maintenance crew to wake up in the morning, walk into work, and figure out what to do for the day.

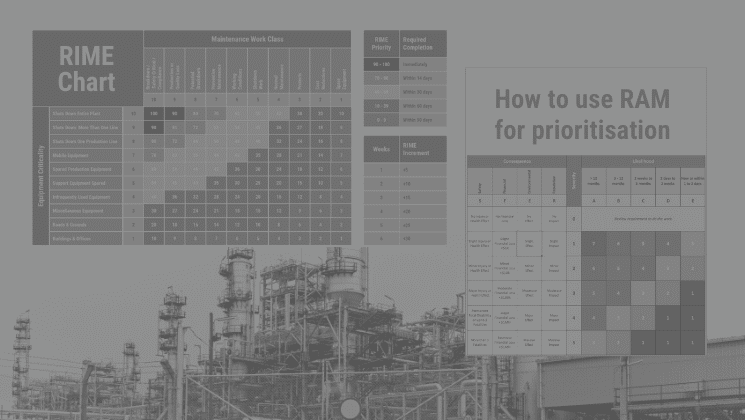

Of course, that is just one reason scheduling increases productivity, others include: better coordination of work between trades, or the grouping of similar work, or work on the same equipment location etc.

If you want to know how to effectively combine Planning with Scheduling to increase your workforce by up to 35% WITHOUT hiring new people…

Then check out our online course on Maintenance Planning & Scheduling using the link below.